A.P.L. Industries

Mfg.: Cement Pipe Machinery & Concrete Block Making Machinery

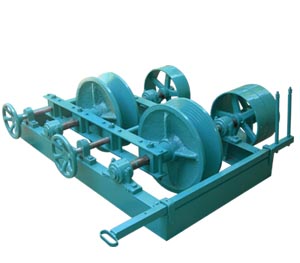

The Reinforced cage is first prepared on the collapsible reinforcing machine by hand process. The cage is then placed inside the pipe mould, which is then hoisted up and mounted horizontally on the Runner machine. It is rotated by 'speed veriater Machine. The rotation is kept slow in the beginning and then the speed is increased. The concrete mixture is prepared material by mixing cement stone, metal and send respectively. The cement concrete is fed into the moulds during rotation, which spreads inside evenly. The time required for completion of this operation depends upon the diameter and class of the pipe. The pipes are kept mould for 24 hours. On the following day the pipes are removed from the moulds and submersed in water in the curing tank for about 15-20 days depending upon the class of the pipe the specimen of the pipes are subject to the following tests viz : 1- Hydrostatic pressure test , 2- Three edge bearing test, 3 - Absorption test.

Quality Control and Standards :

The Bureau of Indian Standards has formulated IS 458 :2003, For maintaining quality of the product.

Model

|

Size

|

Diameter

|

RM

1 |

4Feet |

80

to 300mm |

RM

2 |

2Meter |

80

to 300mm |

RM

3 |

2.5Meter |

80

to 300mm |

RM

4 |

2.5Meter |

150

to 900mm |

RM

5 |

2.5Meter |

600

to 1200mm |

RM

6 |

2.5Meter |

900mm

& Above |

| Suitable for all type of cement pipe like Plane Ended, Flush Joint, Spigot & Socket Type. | ||

| Size : 80 mm to 2600 mm | ||

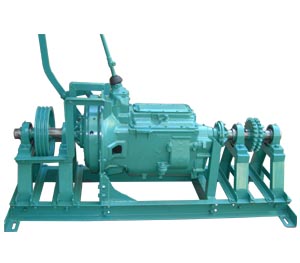

Model |

Size |

Diameter |

SVM

1 |

4 Feet |

80

to 300mm |

SVM

2 |

2 Meter |

80

to 300mm |

SVM

3 |

2.5 Meter |

80

to 900mm |

SVM

4 |

2.5 Meter |

80

to 1200mm |

SVM

5 |

2.5 Meter |

80

to 2600mm |

| Suitable For Above Runner Machine. | ||

| Model | Size | Diameter |

| CRM 1 | 4 Feet | 150 to 300mm |

| CRM 2 | 2 Meter | 100 to 150mm |

| CRM 3 | 2 Meter | 150 to 300mm |

| CRM 4 | 2.5 Meter | 150 to 450mm |

| CRM 5 | 2.5 Meter | 450 to 1200mm |

| CRM 6 | 2.5 Meter | 900mm & Above |

Machine can be run by manually and by electrical motor. (Optional) |

||

Suitable

for all type of cement pipe like Plane Ended, Flush Joint, Spigot

& Socket Type. |

||

Tilting

Drum type,One bag capacity Cast Iron / Mild Steel Body with suitable Frame,Taper Roller Bearings and Metal bushing

Pinion Shaft. |

Foundation

type (Suitable for Cement pipe Unit). |

It is used in option of speed Variator Machine. It is Suitable For 80 mm to 2600 mm Dia Pipe in all class. It has Fixed RPM at 5 different Speed. |

| 2meter & 2.5 meter length are available. |

| All Class of Moulds Are Available in Plane Ended, Flush Joint, Spigot & Socket Type, |

| Moulds are Complete with M.S.Sheet/Plate, Angle/Flat,Tie rods, Nutbolts, C.I. Endrings. |

| (Note: Rings can be made from Mild Steel also.) |

Three Edge Load Testing

Machine Complete with Hand

Operated Hydraulic Jack, Pressure Gauge.Suitable to test

Pipe of all classes upto

1200mm diameter, 2.5 meter length with suitable frame. |

It

is also avalable in One Jack, Two Jack and Three Jack Model. |

| 80mm to 2600mm |

| Model | Size | Diameter |

| PTM 1 | 2 Meter | Up to 300mm |

| PTM 2 | 2.5 Meter | Up to 1200mm |

| PTM 3 | 2.5 Meter | Up to 2600mm |

| Complete with M.S. Frame, Pressure Gauge, Screw Type/ Hydraulically Hand Operated / Hydraulically Motor Operated | ||

| Suitable to test 150mmx150mm Concrete cube |

| Complete with M.S. Frame, Spacers, Hydraulic Jack wiyh Hand operated oil pumping unit. |

C.I. Moulds for Different Sizes. Complete with Base Plate. |

It

is used for concrete put from one side to another side of runner. |

| Model | Size |

| T - 1 | 4 Feet (Bearing Type) |

| T - 2 | 2 Meter (Bearing Type) |

| T - 3 | 2.5 Meter (Bearing Type) |

| T - 4 | 2.5 Meter (Bearing Type) |

| T - 5 | 2.5 Meter (Bearing Type) |

It

is used for finished pipe put in to different Raw. It is available

in bearing type. |

|

Suitable for 80 mm to 2600 mm Diameter Pipe. It is available in various capacity such as 5 HP, 7.5 HP, 10 HP, 15 HP, 20 HP, 25 HP, 30 HP. It is power Saver and maintainence free. it is better option of Speed Variator and Gear Box. |